As part of the suite of planning platforms, we have developed a preconfigured solution for strategic analysis. This solution has an excellent time-to value return.

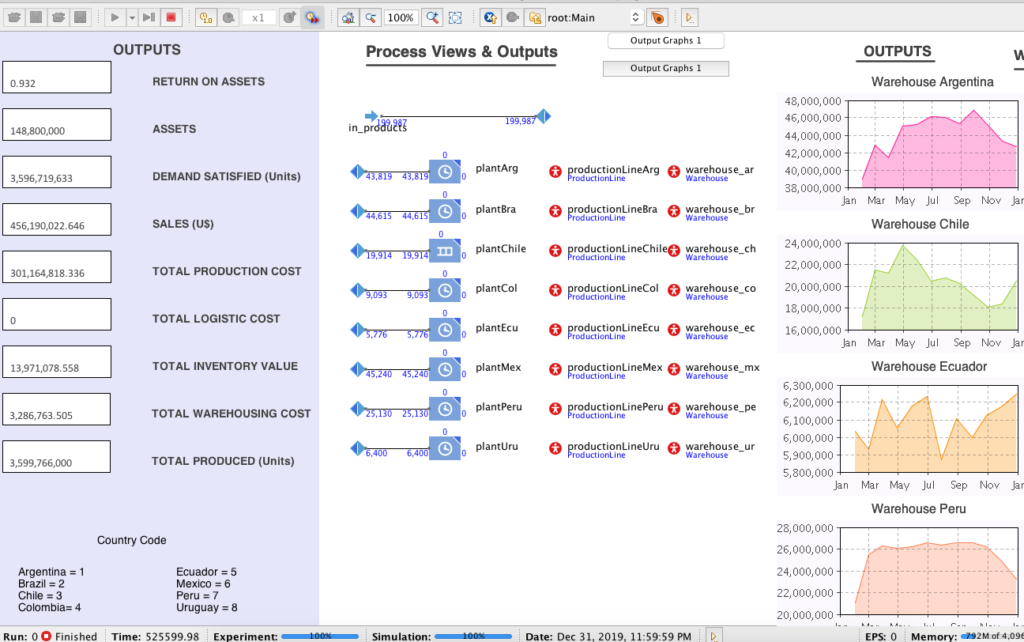

Any company with multiple manufacturing plants needs to decide where to produce and where to allocate the inventory according to hubs network! and be able re-evaluate this decision as conditions as costs, efficiency rates, labor schedule, etc change constantly.

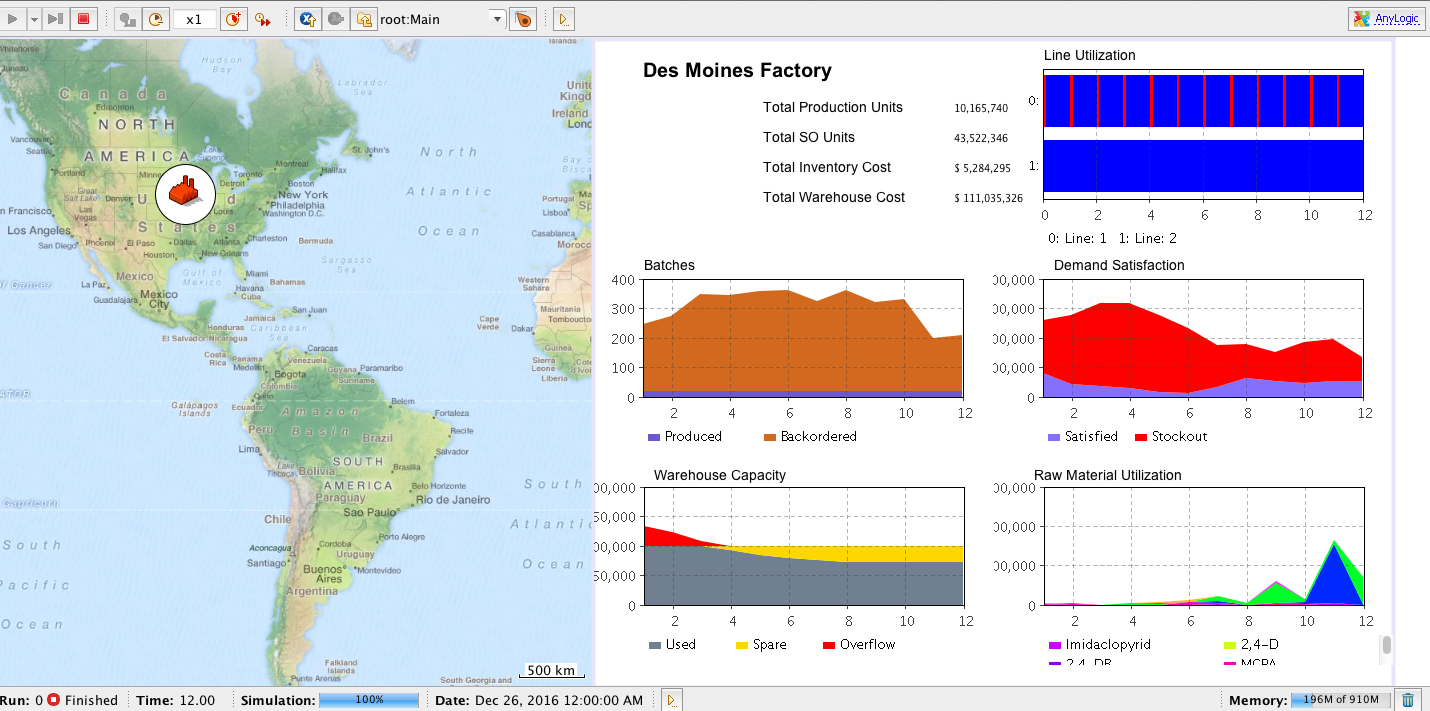

It is a digital twin representation developed with Anylogic and data structure integrated in SAP analytic cloud. It builds and evaluate the feasible production plans combining production and logistics network, calculating production costs, warehouses availabilities and costs on the move, while running the model as external conditions change. So, once the matrix of feasible scenarios has been found by the simulator, the embedded optimizer of the solution will build a production plan according to your goals. Usually ROA or safety stock are used to optimize.

Multiple runs experiments will allow to compare the estimated key indicators for each scenario. Sensitivity analysis is a great indicator. A tornado analysis and Montecarlo experiment are also part of the features.